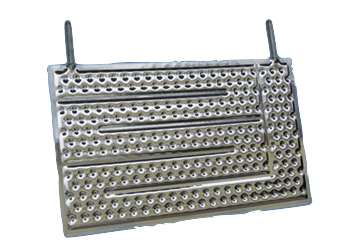

Laser welding pillow plate:

Heat exchange pillow plate is machined by full automatic laser welding and forming process. Its unique pillow structure makes fluid into optimum turbulence state to achieve high efficient heat exchange. It also boasts various advantages such as dust proof, high temperature and high pressure resistance and easy cleaning, etc.

Pillow plate concept:

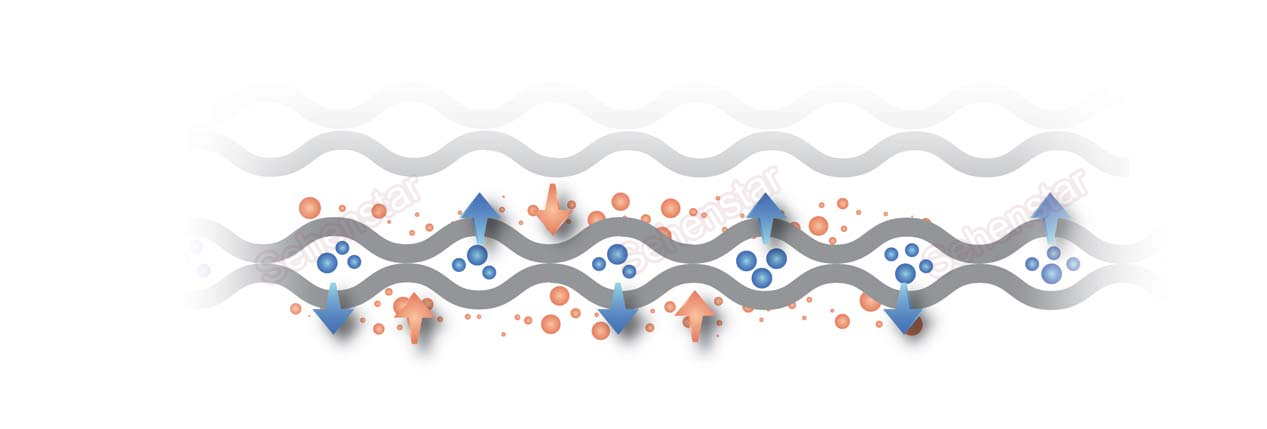

Pillow plate is laser welded by two plates all around and in the middle area full of weld flowers. After the forming process, the inner part of the heat exchange plate forms a pillow type cavity. Pillow design creates excellent turbulence and provides self supporting structure. In practical applications, the additional welding path is often added in the pillow heat exchange plate, in order to adjust and control the flow of fluid into and out of the heat exchange plate nozzle position, the fluid velocity and flow rate inside plate, so as to optimize the heat exchange effect.

Pillow plate advantages:

1) Excellent turbulence design, high heat exchange coefficient

2) High welding reliability

3) Small external surface resistance, not easy to product dirt

4) High temperature and high pressure resistance

5) Wide channel, low pressure drop, easy to clean

6) Flexible shape to maintain optimal heat exchange effect

![[field:title/]](../skins/default/images/insidepage/products_img.jpg)